Cricket Balls

- Home

- Cricket Balls

Crafting Excellence: The Art of Leather Ball Making

1. Leather Selection: Choose high-quality leather hides suitable for cricket balls.

2. Cutting: Cut the leather into precise shapes using templates.

3. Shaping: Shape the leather pieces to form the outer shell of the ball.

4. Stitching: Stitch the shaped leather pieces together to create the ball’s shell.

5. Core Insertion: Insert a solid cork core into the stitched leather shell.

6. Winding: Wind layers of twine around the cork core to add strength and shape.

7. Layer Application: Apply layers of cork and rubber to achieve desired weight and bounce.

8. Waterproofing: Treat the ball with waterproofing agents to protect it from moisture.

9. Polishing: Polish the ball to enhance its appearance and durability.

10. Quality Inspection: Inspect each ball for weight, shape, and seam quality to ensure it meets standards.

This process ensures each leather ball is crafted to deliver optimal performance and durability on the field.

2. Cutting: Cut the leather into precise shapes using templates.

3. Shaping: Shape the leather pieces to form the outer shell of the ball.

4. Stitching: Stitch the shaped leather pieces together to create the ball’s shell.

5. Core Insertion: Insert a solid cork core into the stitched leather shell.

6. Winding: Wind layers of twine around the cork core to add strength and shape.

7. Layer Application: Apply layers of cork and rubber to achieve desired weight and bounce.

8. Waterproofing: Treat the ball with waterproofing agents to protect it from moisture.

9. Polishing: Polish the ball to enhance its appearance and durability.

10. Quality Inspection: Inspect each ball for weight, shape, and seam quality to ensure it meets standards.

This process ensures each leather ball is crafted to deliver optimal performance and durability on the field.

Complete Range of Cricket Balls

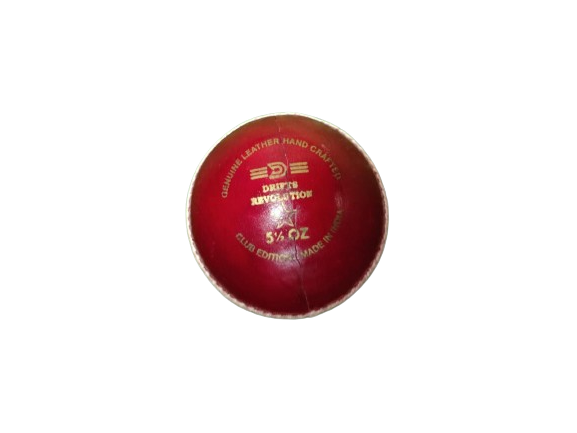

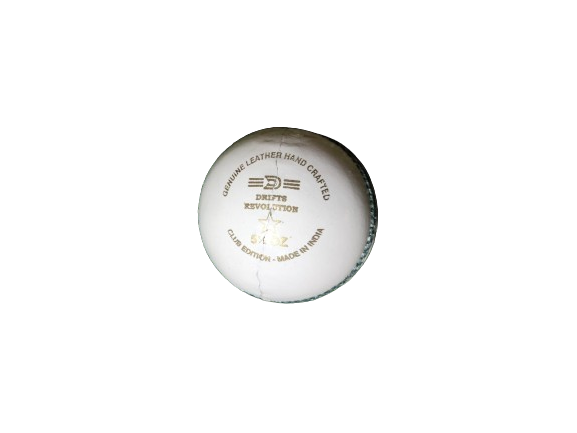

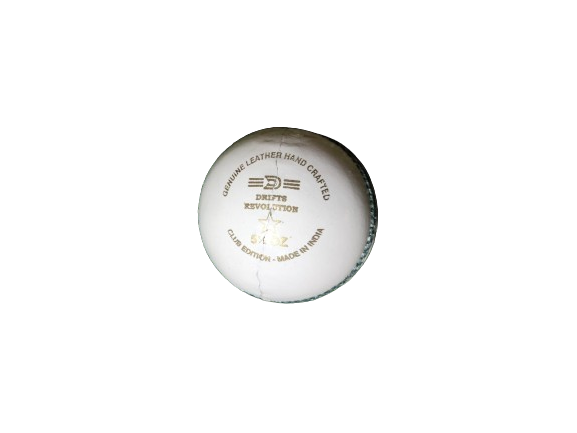

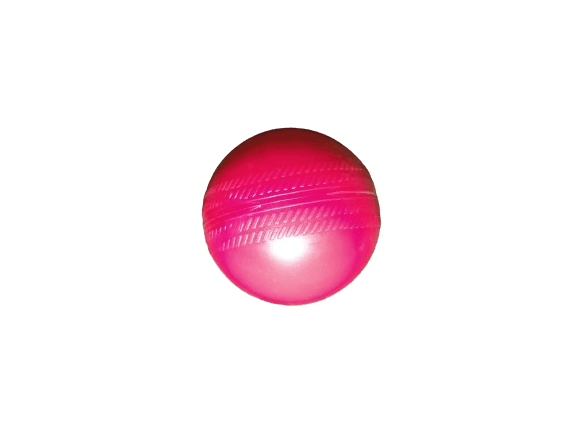

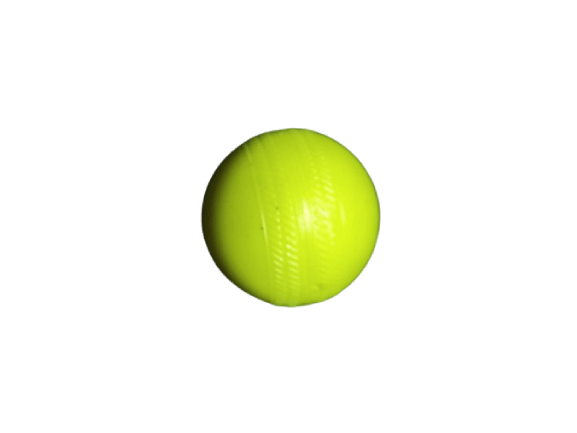

Drifts Club Tournament Special offers top-quality leather balls designed for durability and performance across various formats: 90, 50, and 40 overs, as well as T20, available in both white and red colors. Additionally, our range includes durable plastic balls in 80g and 100g variants, catering to different training and match needs.

50 Overs Red Leather Balls

40 Overs Red Leather Balls

50 Overs White Leather Balls

40 Overs White Leather Balls

Plastic Balls 80 & 100 Grams

80 Grams

100 Grams

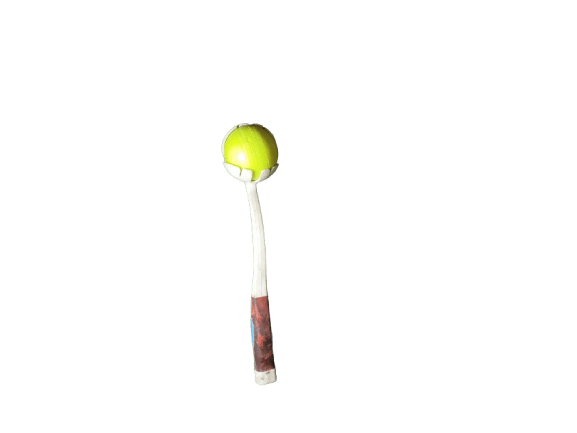

Plastic Ball Side-Arm

Discover your ideal gloves with just a click! With our dedication to excellence, expect delivery in 4 days. For images or assistance, connect with us on WhatsApp.